Ethical Luxury: Why a Genuine Habesha Garment Takes Weeks to Create

Habesha garments, with their intricate designs and flowing silhouettes, are more than just clothing; they are a vibrant tapestry woven with history, culture, and skilled craftsmanship. These traditional attires, primarily from Ethiopia and Eritrea, are often reserved for special occasions like weddings, holidays, and cultural celebrations, each thread telling a story of heritage. But what goes into creating these beautiful pieces? Let's take a deep dive into the fascinating manufacturing process of authentic Habesha garments.

1. The Foundation: Sourcing the Finest Cotton

The journey of a Habesha garment begins with the selection of raw materials. Authentic Habesha clothes are predominantly made from locally sourced, high-quality cotton. The cotton is carefully chosen for its softness, durability, and ability to hold intricate designs. In many traditional settings, the cotton is still hand-picked, ensuring only the best fibers are used.

2. From Fiber to Thread: The Spinning Process

Once the cotton is gathered, it undergoes the meticulous process of spinning. Traditionally, this was done by hand, using a drop spindle. Artisans would skillfully draw out and twist the cotton fibers into fine, strong threads. While some modern workshops might use machines for this step, many traditional weavers still prefer hand-spinning, believing it contributes to the unique character and feel of the fabric. The resulting threads, known as "kal," are then ready for the next crucial stage.

3. Dyeing: Infusing Color and Meaning (Optional but Common)

While many traditional Habesha garments are known for their pristine white base, some designs incorporate vibrant colors. When dyeing is involved, natural dyes derived from plants, minerals, or even insects are often preferred. These natural pigments not only produce rich, earthy tones but also carry cultural significance. The threads are carefully immersed in the dye baths, allowing the color to deeply penetrate each fiber.

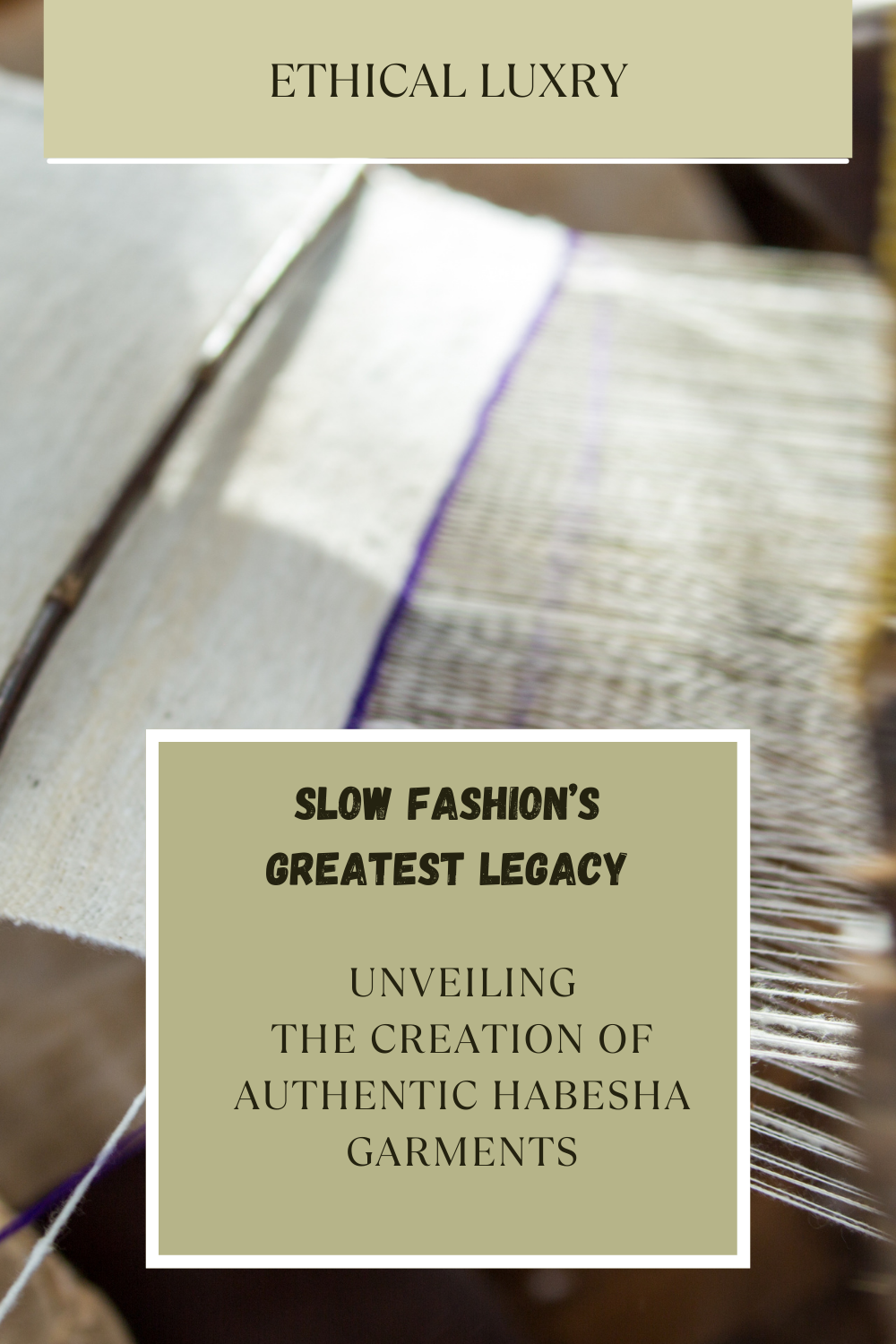

4. The Heart of the Craft: Weaving the Fabric

This is where the magic truly happens. The dyed or undyed cotton threads are meticulously loaded onto a traditional handloom.

These looms, often passed down through generations, are operated by skilled weavers who use a rhythmic dance of their hands and feet to interlace the warp (longitudinal) and weft (transverse) threads.

The weaving process for Habesha garments is distinct for its creation of narrow strips of fabric, typically about 30-40 centimeters wide. These strips, known as "shemma," are a hallmark of authentic Habesha weaving. The intricate patterns and textures are often created by varying the tension and interlacing of the threads, a testament to the weaver's expertise.

5. The Art of "Tilet": Hand-Embroidered Borders

What truly sets Habesha garments apart are the exquisite hand-embroidered borders, known as "tilet" (pronounced "tee-let").This can also be done by machines for some designs.

These elaborate designs are meticulously stitched onto the woven fabric strips, usually at the edges of the garment, neckline, and cuffs.

"Tilet" patterns are rich in symbolism, often featuring geometric shapes, crosses, and other motifs that reflect cultural beliefs and regional variations. The colors used in "tilet" are vibrant and carefully chosen to complement the main fabric. This embroidery is a time-consuming and labor-intensive process, often taking days or even weeks to complete, depending on the complexity of the design.

6. Assembly: Bringing the Pieces Together

Once the "shemma" strips are woven and the "tilet" embroidered, the garment begins to take shape. The narrow strips of fabric are carefully stitched together by hand to form the larger panels of the dress (kemis) or shawl (netela/gabi). The precision of these seams is crucial for the garment's drape and overall aesthetic.

Tailors, often working closely with the weavers and embroiderers, then cut and shape the assembled fabric according to traditional patterns for various garments, such as:

Kemis: The women's main dress, typically ankle-length with long sleeves.

Netela: A thin, delicate shawl worn by women over the kemis.

Gabi: A thicker, warmer shawl, often worn by men and women in cooler weather.

Kaba: A ceremonial cloak.

7. Finishing Touches: Washing and Ironing

The final steps involve washing and carefully ironing the garment. This not only cleans the fabric but also helps to set the stitches and give the garment its characteristic smooth finish. Traditional methods might involve hand-washing with natural soaps and air-drying.

A Legacy of Craftsmanship

The manufacturing of authentic Habesha garments is a testament to the enduring power of traditional craftsmanship. From the initial cotton plant to the final stitch, each step is imbued with dedication, skill, and a deep respect for cultural heritage. These garments are not just clothes; they are wearable art, embodying centuries of tradition and the intricate beauty of Ethiopian and Eritrean culture. When you wear an authentic Habesha garment, you are not just donning a dress; you are carrying a story.